How to Avoid Food Safety Incidents and Costly Compliance Failures: An Owner’s Guide

A decade ago, a Listeriosis outbreak at a manufacturing facility of Texas-based Blue Bell Creameries in 2015 left three people dead and ten more hospitalized. A federal court sentenced the iconic ice cream company to pay more than $17.25 million in criminal penalties for distributing ice cream products manufactured in unsanitary conditions.

The company also recalled more than 8 million gallons of ice cream and had to lay off more than 1,400 employees, over a third of the company’s workforce.

Beyond the loss of human life, the fallout from the outbreak was devastating to Blue Bell’s bottom line and its public image.

The outbreak was one of the more extreme food safety cases in recent decades. But it still bears a lesson for all food companies - a reactive approach is always more expensive than a preventive one.

In this free Rootwurks guide, you’ll discover some common-sense strategies and best practices companies can take to ensure they meet compliance guidelines and avoid devastating food safety incidents.

Step 1:

Commit 100% to Training

and Safety Culture

According to the guidelines of the Food Safety Modernization Act (FSMA), employees who handle food and their supervisors must “receive adequate training, as appropriate to the person's duties, upon hiring, and periodically thereafter, at least once annually.”

But to build a strong culture of safety and compliance, training should be reinforced every day during the workflow - and not simply be a once-a-year hassle to rush through.

Management must show commitment

To train teams for compliance and food safety, management must take the lead and commit the time, money, and effort necessary to improve the workplace culture.

How management can take the lead on safety and compliance:

-Invest the time and money needed-Model best practices on the work floor

-Be present at company facilities and help supervise operations

-Implement frequent quizzes and reviews - don’t rely on once-a-year refreshers

-Empower employees to speak out about compliance and safety issues

-Praise employees for success in compliance and safety training

Understand the Why

For employees to fully buy-in on safety and compliance, management must explain the “why” about food safety and training. Employees must see the importance of safety, training, and compliance, the reasons behind the processes they perform, and be empowered to take the lead on these tasks during the work day.

Step 2:

Don’t Wait for the Regulators - Audit Your Operations and Leave No Stone Unturned

In food safety, auditing your operations is one of the best ways to be proactive on compliance and safety.

Internal audits help companies meet all necessary safety and compliance guidelines and find, assess, and eliminate safety risks before the next compliance visit.

With internal audits, companies ensure:

-Relevant and required training is being performed-Food safety compliance guidelines are being met

-New regulatory guidelines are implemented as they go into effect

-Corrective actions have been taken for previous issues

-Risk assessment processes are working as needed

-Recordkeeping is performed as needed

How to Start Auditing Your Company Today

Step 1: Establish your audit requirements

Determine what you need to audit to meet your compliance and safety demands. This can include specific industry standards, individual regulations, recall prevention protocols, and more. Develop a plan of attack and start training.

Step 2: Perform a risk assessment

Highlight the most important areas of concern and work down the list in order of severity. This will help you determine risks for each process and product.

Step 3: Build your audit team

Appoint a trusted team member to supervise the internal audit and give them the authority and confidence to manage the team and assign tasks across multiple departments and roles.

Step 4: Set a schedule

Determine how frequently you can audit your operations to meet compliance and safety needs. Your risk assessment will indicate how often to audit and where to focus your efforts.

Step 5: Prepare your documentation

Make sure to keep all your paperwork in order. This includes records of past compliance and auditing tasks and records on employee training. This will help your team perform audits in a more targeted, well-informed, and efficient manner.

Step 3:

Train Your Team for Risk Assessment

Internal audits are critical for building a preventive approach to food safety, but there are also two training courses that help companies create safer, more compliant workplaces.

Hazard Analysis and Critical Control Points (HACCP) Training

HACCP guidelines are based on 7 principles, all of which can help companies better meet compliance demands and avoid costly food safety incidents:

• Determine the critical control points

• Establish critical limits

• Establish monitoring procedures

• Establish corrective action

• Establish verification procedures

• Establish recordkeeping and documentation procedures

Preventive Controls Qualified Individual

(PCQI) Training

Under FDA guidelines, food companies must have a food safety plan that is created and implemented by a Preventive Controls Qualified Individual. Training to become a PCQI typically runs about 20 hours, and covers all types of critical food safety topics such as:

-Food Safety Plan Overview for Preventive Controls for Human Food

-Hazard Analysis for Human Food

-Current Good Manufacturing Practice and Prerequisite Programs for Human Food

-Biological Food Safety Hazards for Human Food

-Food Allergen Preventive Controls for Human Food

-Preventive Controls Determination for Human Food

-Supply-Chain Preventive Controls for Human Food

-Food Safety Plan Implementation and Management for Human Food

-Recall Plan for Human Food

Like HACCP training, learning the PCQI guidelines helps learners gain a comprehensive understanding of hazard analysis and preventive controls. When implemented in the workplace, these guidelines help elevate a company’s safety culture and improve performance on compliance tasks and risk mitigation.

Step 4:

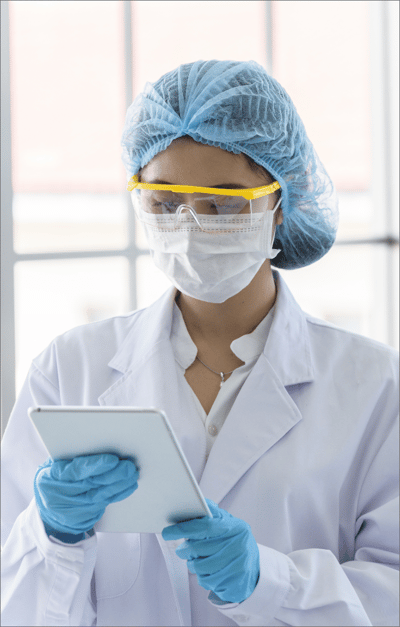

Verify and Validate Training

You can train your team for compliance, safety, and risk management, but you can’t just check a box after each training session and assume you’ve covered all of your bases. Instead, you must be able to verify and validate employee retention and execution of the training if you want to reduce risk in your daily operations.

For successful compliance and safety training, management must:

Ensure training is engaging, practical, and designed to be reinforced “in-the-flow-of-work” to boost retention

Track employee proficiency on training and record who has mastered the material and who needs more training

Utilize tools such as quizzes and assessments to track employee understanding of key concepts and find areas for improvement

Build corrective action plans for each specific employee to determine where and how to reinforce their training and risk management actions

Establish benchmarks for compliance and safety training and track how employees are meeting these personalized goals

Keep comprehensive records of all training actions taken, and ensure records can be produced quickly in the event of a regulator visit

Every company wants to stay on top of its compliance and safety training needs. But if you don’t put the tools and processes in place to verify and validate safety training - and build corrective action plans where needed - then your ability to stay ahead of compliance and safety and mitigate risk will be significantly compromised.

Step 5:

Invest in a Sophisticated Learning Management System (LMS)

Investing in a Learning Management System (LMS) is one of the most impactful steps companies

can take to make it easier to train their teams for compliance.

With a Learning Management System, you can:

-Build custom training content that speaks to your specific compliance needs

-Verify and validate employee performance on training, and build corrective actions

-Keep precise records of compliance and training

-Create targeted training paths for individual employees and facilities

-Enhance safety and compliance culture through regular, reinforced learning.

Rootwurks provides food manufacturing companies with an LMS that combines comprehensive safety training and compliance management in one platform.

The Rootwurks Way

Almost There

(But Not Quite)

The Old Way

Step 6:

When in Doubt, Call in the Experts

Most food industry professionals didn’t enter the business because they had an innate understanding of compliance obligations. But these guidelines are a necessary obligation, and they leave little room for error.

When building out your food safety plan and compliance management protocols, hiring an outside consultant can be of great assistance, especially if you’re launching new product lines or opening a new facility.

Here is just a quick glance at what a food safety and compliance consultant can provide:

• Risk Assessment for Facilities and Products• Guidance to Help Your Team Understand Compliance Demands

• Assistance with Building Training Plans for Compliance

• Guidance on Formulating and Implementing Your Food Safety Plan

When it comes to compliance, being unclear on the guidelines won’t help you avoid a fine. Hiring an outside consultant can help ensure that you meet your obligations and develop more efficient and targeted ways to do so, ultimately contributing to a stronger overall culture of safety.

Transform Your Safety Culture:

Schedule a Call

Book a call to learn how Rootwurks can optimize training, safety, and compliance for your company.