Report::

The Biggest Training Challenges in the Food Manufacturing Industry

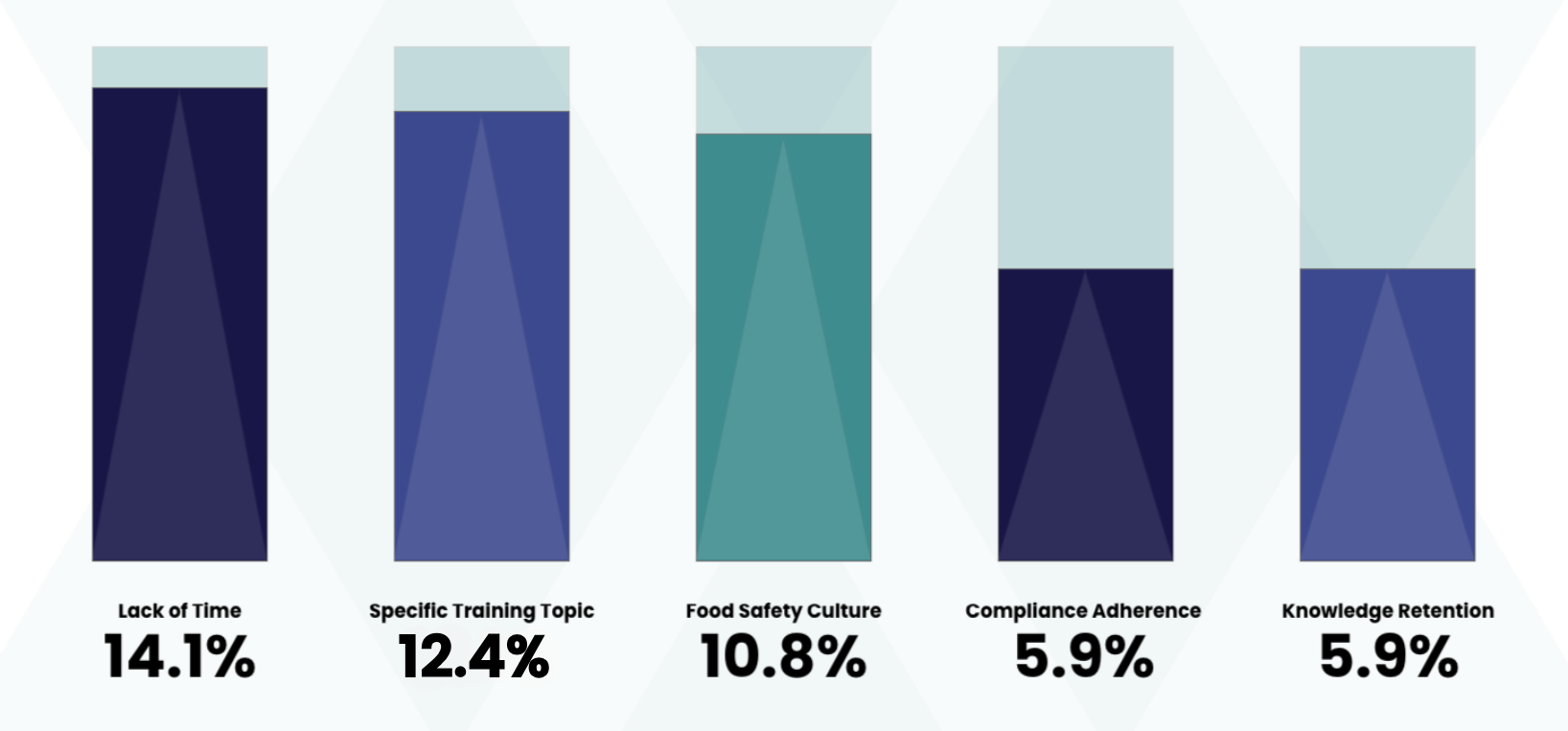

Rootwurks surveyed 185 professionals in food manufacturing and asked, “What is your biggest training challenge?"

In this free report, we share these findings and provide insights on how companies can address the challenges of food safety training. We also highlight the biggest challenges based on job seniority, company size and more.

The Top Five Training Challenges in the Food Manufacturing Industry

The most frequently mentioned training challenge was “lack of time,” reported by 14.1% of respondents. This was followed by “specific training topic” (12.4%) and “food safety culture” (10.8%). The other 13 responses covered a wide range of challenges, such as knowledge retention, lack of leadership buy-in, and language barriers.

The answers given varied significantly according to the respondent’s job title and the size of the company they work for. Continue reading to discover how.

Complete Breakdown of Training Challenges

| Pain Point Category | Description (Concise) | Percentage |

| Lack of Time | Employees and management struggle to find time for training due to busy schedules and operational demands. | 14.1% |

| Specific Training Topic | Employees struggle with a specific training topic, such as Listeria Prevention or HACCP. | 12.4% |

| Food Safety Culture | Challenges in establishing and maintaining a strong food safety culture. | 10.8% |

| Compliance Adherence | Difficulties in ensuring employees adhere to regulatory requirements and industry standards. | 5.9% |

| Knowledge Retention | Issues with employees retaining information and skills learned during training. | 5.9% |

| Training Effectiveness | Concerns about whether training programs achieve intended learning outcomes and improve performance. | 4.9% |

| Lack of Leadership Buy-In | Difficulties gaining leadership support and commitment for training initiatives. | 4.9% |

| Attendance and Participation | Challenges getting employees to attend and actively participate in training. | 4.3% |

| Lacking Training Content | Difficulties due to the absence of adequate, up-to-date, or relevant training materials. | 4.3% |

| Audits | Difficulties related to conducting, preparing for, or understanding audits. | 3.8% |

| Training Comprehension | Difficulties in ensuring employees understand the information presented during training. | 3.8% |

| Language Barriers | Challenges in delivering training to a workforce with diverse language backgrounds. | 3.8% |

| Workforce Engagement | Difficulties motivating and engaging employees in the training process. | 3.2% |

| Turnover | Challenges related to high employee turnover rates impacting training effectiveness. | 3.2% |

| Lack of Workforce | Difficulties associated with having an insufficient number of employees for tasks and training. | 2.7% |

| Lack of Trainer Resource | Challenges related to having adequate trainers or qualified instructors. | 2.2% |

| Recordkeeping | Difficulties maintaining accurate and accessible records of training activities. | 1.6% |

| Lack of Consistency | Challenges ensuring consistency in processes, practices, and training delivery. | 1.1% |

| Internal Audits | Specific challenges related to conducting or understanding internal audits. | 1.1% |

| Training Deployment | Challenges in the practical implementation and delivery of training programs. | 1.1% |

| Change Management | Challenges implementing changes and getting staff to accept them. | 1.1% |

| Training Verification & Validation | Challenges confirming that training meets standards and that employees are executing correctly. | 1.1% |

| New Hires/Onboarding | Difficulties effectively training and integrating new employees. | 0.5% |

| Outdoor Training | Specific challenges associated with conducting training in outdoor environments. | 0.5% |

| Innovation | Difficulties or desires related to fostering innovation. | 0.5% |

| Corrective Action Management | Struggles implementing and managing corrective actions. | 0.5% |

| Budget | Concerns about resource allocation and financial constraints for training. | 0.5% |

It Starts at the Top:

What Senior Leadership Told Us About Training Challenges

Lack of leadership buy-in was mentioned as a training challenge by 4.9% of respondents. But what did senior leadership cite as the top training challenges?

Our report defines senior leadership as individuals who hold top-level management positions within an organization, such as Director, General Manager, CEO, VP, and owner.

One interesting finding that stands out is that 10.7% of respondents in senior leadership positions cited “lack of leadership buy-in” - more than double the percentage of overall respondents who cited this pain point.

This would appear to indicate that building a robust food control system doesn’t only require management buy-in; it requires ALL senior management to be on the same page and commit the time, resources, and leadership necessary to meet the task.

The percentage of senior leaders who mentioned a lack of time was twice that of the overall respondents.

The results suggest that senior leadership is not immune to the training headaches that frustrate middle-management and front-line workers, and needs training content that hones in on their specific food safety and compliance needs without taking time away from the workflow.

But first, they need to get the rest of the senior management on board.

The Top 5 Training Pain Points for Senior Leadership:

Specific Training

32.1%

Lack of Time

28.6%

Lacking Training Content

17.9%

Lack of Leadership Buy-In

10.7%

Compliance Adherence

10.7%

Stuck in the Middle

Which Training Challenges Most Frustrate Middle Management?

Senior management establishes the company's training strategy. However, middle management is the eyes and ears on the ground, ensuring that safety training is effectively implemented within the workflow.

Our survey defines middle management as individuals who manage teams or departments and are responsible for implementing the strategies set by senior leadership. These individuals have job titles such as supervisor, coordinator, manager, and specialist.

The responses make sense when one considers that middle management professionals are responsible for supervising training, safety, and compliance in real time at food and beverage manufacturing facilities.

They understand the time crunch on the manufacturing floor and recognize the importance of implementing food safety training that doesn’t disrupt team members' workflow.

Unlike senior management, they are much more likely to struggle with language barriers and can see firsthand how and where employees are—and aren’t—retaining training knowledge.

They are also more likely to be intimately aware of what a strong food safety culture should look like—and when their company hasn’t yet met the standard.

The Top 5 Training Pain Points for Middle Management:

Lack of Time

42.2%

Food Safety Culture

23.5%

Knowledge Retention

17.6%

Language Barriers

8.8%

Specific Training Topic

8.8%

Trouble on the Front Line:

The Training Challenges of Frontline Employees

Elevating food safety culture and training requires the commitment of all levels of management. But it is the frontline workers who bear the brunt of the responsibility for learning, retaining, and implementing safety training.

In our survey, this category of employees includes all those outside of middle and upper management, including frontline workers and individual contributors. Their job titles were varied and included technician, consultant, and quality assurance specialist, among others.

The frontline employees cited compliance adherence as a challenge more than any other level of employee (17.1%), which may be explained by the fact that the burden for carrying out compliance-related tasks lies on their shoulders. These employees are also the only ones to name training comprehension (14.6%) in their top 5, besides audits (14.6%). They did not rank leadership buy-in in their top 5, which may indicate a sort of detachment from where executive decisions are made.

An interesting aspect of their answers is how much they indicate challenges with implementing training or safety tasks assigned by management. They are the ones who would need to carry out the actions needed for audits, and potentially the ones who may feel to blame if the company doesn’t do well during a compliance visit.

The high frequency with which training comprehension was mentioned could indicate the extent of which frontline workers are tasked with training that is not later reinforced to confirm comprehension or knowledge retention.

These results provide further evidence of the importance of ensuring that training is practical, self-paced, and designed to be reinforced during the workday.

The Top 5 Training Challenges for Frontline Workers

Food Safety Culture

42.2%

Specific Training Topic

26.8%

Compliance Adherence

17.1%

Audits

14.6%

Training Comprehension

14.6%

Big Challenges

No Matter the Company Size

Some challenges are universal. Food companies must avoid recalls, meet their compliance requirements, produce safe, high-quality products, and protect their brand reputation in the eyes of the public.

But the everyday challenges that companies face can vary as they grow in size, as the results of our survey indicate.

It may not be surprising, but 41.2% of respondents who work for companies with 50 or fewer employees said that lack of time is their biggest challenge. These often short-staffed companies also struggle with finding enough hands on deck to handle compliance adherence, which was cited by 14.7% of these respondents.

Respondents who work for companies with 51-200 employees cited food safety culture (37.5%) and lack of time (37.5%) as the top two challenges they face. This result illustrates how as companies expand, maintaining training and quality standards can become more difficult.

For companies with 501-1000 employees, training effectiveness (mentioned by 40% of respondents) becomes more important and more difficult to monitor. These larger companies can also face greater difficulty in keeping employees engaged in training (20%) and maintaining a consistent food safety culture across company locations (20%).

For the biggest companies, those with 1001 to 5,000 or more employees, keeping large numbers of people engaged in training is especially difficult. It is also more complicated to implement a robust food safety culture across such a large workforce. In addition, respondents from the largest companies were also the most likely to cite lack of leadership buy-in (cited by at least 20% of respondents). This may indicate how in larger organizations, it can be harder to get everyone on the same page.

0-50 Employees

Lack of Time

41.2%

51-200 Employees

Training Effectiveness

40%

500-1000 Employees

Training Effectiveness

41.2%

1001-5000 Employees

Attendance/Participation

41.2%

5000+ Employees

Lack of Time

40%

Unique Companies, Unique Training Demands

Among other findings, the report makes it clear that the challenges companies face are not universal. It highlights clear differences in the challenges that small companies and larger firms face with training, and how these challenges evolve as companies scale up.

In addition, the second most cited pain point for training was a "specific training topic.” This means that they are facing challenges meeting specific training requirements related to particular skills, processes, or job functions at their company. It is further evidence of how companies have unique training needs that are not universal across the board.

This aligns with the conclusions of a 2015 study in the International Journal of Food Science. In the report, the authors wrote that “training in all areas of food safety does not imply improved performance in food safety issues. Training contents should be directed toward the specific needs of the individual food handlers and their area of work in the food industry.”

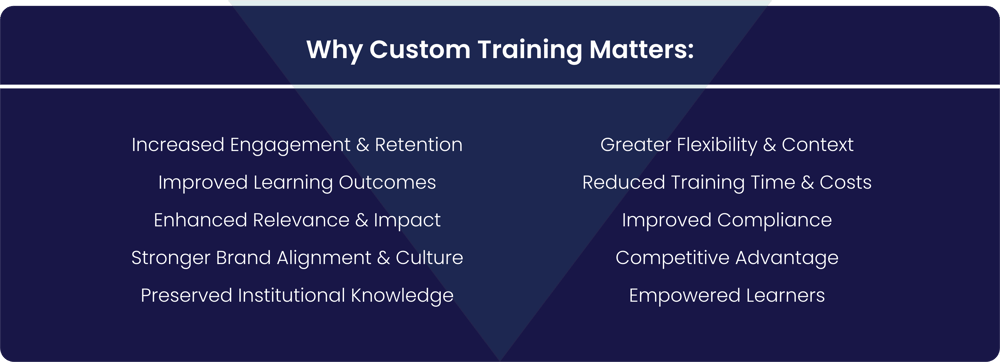

The Need for Custom Training Solutions

Generic, off-the-rack training often falls flat. It’s generalized and doesn’t always address a company’s specific training needs and is less engaging and less likely to be retained.

Custom training allows companies to tailor the content to focus on specific skills and knowledge gaps in the company's workforce, helping them create more efficient, targeted training. This saves time and money, and produces better training outcomes.

Bespoke training is more practical and can be easily reinforced during daily operations, further boosting retention.

Custom training also helps bolster the company’s culture and improves consistency in operations across all company locations.

Customization also means companies can integrate their in-house legacy training materials where they see fit

As the report makes clear, every company is unique, and it is imperative that companies build custom training solutions to empower their teams to build a robust food safety culture.

Train Smarter, Train Better

The responses to our Rootwurks food and beverage industry survey illuminate much of what it means to be a food and beverage industry professional in 2025.

Time is at a premium, and regardless of the number of team members you have, your company must fulfill all its compliance and safety obligations. Understanding specific training topics can be highly difficult. Retention is even harder to ensure, especially if the training isn’t practical or relevant and isn’t reinforced during daily operations. Building a safety culture requires the commitment of all employees - and the complete buy-in of company leadership.

To enhance food safety training and create an ironclad safety culture, companies must find ways to maximize efficiency and use time wisely. They need custom training that doesn't waste time on subjects they don’t need to cover, and they need to be able to highlight where employees have proven aptitude - and where they need further instruction.

Time is Money.

Rootwurks Saves Both.

With Rootwurks, companies access custom, comprehensive safety training that seamlessly integrates with the busy work day, helping optimize learning without slowing operations.